- Home > Products > Butterfly Valve >

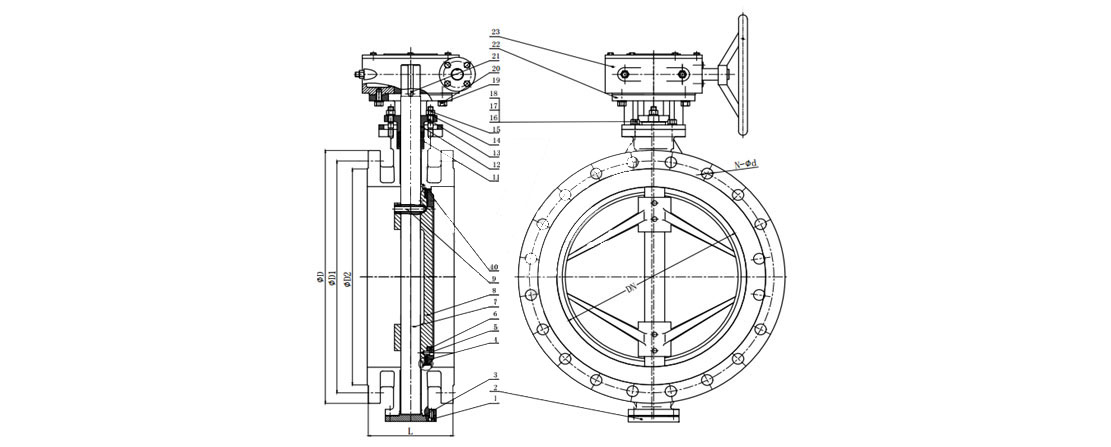

Triple Offset Flanged Butterfly Valve

- Size:

- DN40-DN600

- Pressure:

- PN10,PN16,PN25,Class150

- Body Materials:

- WCB,304,316

- Disc Materials:

- WCB/CF3/ CF3M/CF8/CF8M

- Seat Materials:

- 13cr SS/304/316

- Applicable Medium:

- Water, weak acid base, air, steam, oil, etc

- Send us Email

Product Introduction

Seat Materials: 13cr SS/304/316

Disc Materials: WCB/CF3/ CF3M/CF8/CF8M

Stem Materials: 2Cr13/304/316

End Connection: Wafer,LUG,Flange

Operate: Handle, Worm gear, Pneumatic, Electric-Motorized

Product Features

1. Precision casting valve body. Qualified WCB material. Fine appearance and no trachoma.

2. Solid and heavy valve body.

3. The disc is processed by CNC precision lathe with high precision.

4. Multi-layer sealing ring, which has the both advantages of metal and elastic sealing. Excellent sealing performance in the environment of high and low temperature

5. Stainless steel stem. Double intensity of valve stem after tempering.

6. Each valve will be inspected for shell and seal pressure before leaving factory.

7. The adjusting screw of worm gear is equipped with a protective nut to protect the adjusting screw from damage.

Technical Parameters

| Size | PN16 | 150LB | |||||

| DN | NPS(Inch) | L | D1 | N-d | L | D1 | N-d |

| 50 | 2'' | 108 | 125 | 4-18 | 108 | 120.7 | 4-18 |

| 65 | 2 1/2'' | 112 | 145 | 4-18 | 112 | 139.7 | 4-18 |

| 80 | 3'' | 114 | 160 | 8-18 | 114 | 152.4 | 4-18 |

| 100 | 4'' | 127 | 180 | 8-18 | 127 | 190.5 | 8-18 |

| 125 | 5'' | 140 | 210 | 8-18 | 140 | 215.9 | 8-22 |

| 150 | 6'' | 140 | 240 | 8-22 | 140 | 241.3 | 8-22 |

| 200 | 8'' | 152 | 295 | 12-22 | 152 | 298.5 | 8-22 |

| 250 | 10'' | 165 | 355 | 12-26 | 165 | 362 | 12-26 |

| 300 | 12'' | 178 | 410 | 12-26 | 178 | 431.8 | 12-26 |

| 350 | 14'' | 190 | 470 | 16-26 | |||

| 400 | 16'' | 216 | 525 | 16-30 | |||

| 450 | 18'' | 222 | 585 | 20-30 | |||

| 500 | 20'' | 229 | 650 | 20-33 | |||

| 600 | 24'' | 267 | 770 | 20-36 | |||

| 700 | 28'' | 292 | 840 | 24-36 | |||

| 800 | 32'' | 318 | 950 | 24-39 | |||

| 900 | 36'' | 330 | 1050 | 28-39 | |||

| 1000 | 40'' | 410 | 1170 | 28-42 | |||

| 1200 | 48'' | 470 | 1390 | 32-48 | |||

| 1400 | 56'' | 530 | 1590 | 36-48 | |||

| 1600 | 64'' | 600 | 1820 | 40-56 | |||

| 1800 | 72'' | 670 | 2020 | 44-56 | |||

| 2000 | 80'' | 760 | 2230 | 48-62 | |||

Technical Standard

1.Design and manufacture according to API609.

2.Face to face according to ANIS B16.10.

3.Flange drilling according to CLASS 150/PN10/PN16/PN25

4.Top flange drilling according to ISO 5211.

5.Pressure test according to API598.